1. Overview

????????DRB-M series electric lubrication pump is suitable for units with high lubrication frequency, long piping length and dense lubrication points.Smart lubrication, in the dual-line dry thin oil centralized lubrication system, it is used as a delivery device for supplying grease.

For example, a mobile electric lubrication pump device equipped with a mobile trolley, hose, oil gun and cable is suitable for mobile grease supply lubrication with low lubrication frequency, few lubrication points and large oil supply volume, which makes it inconvenient to use single-machine equipment with centralized lubrication.

This series of lubrication pumps are electric high-pressure plunger type. The working pressure can be adjusted arbitrarily within the nominal pressure range and has double overload protection. The oil storage barrel has an automatic oil level alarm device. If the lubrication pump is equipped with an electrical control box, it can realize fully automatic control of the two-line centralized lubrication system and monitor the system.

2. Technical parameters

The medium used is grease (NLGI 0#-3#) with a cone penetration of not less than 220 (25°C, 150g) 1/10mm and lubricating oil with a viscosity grade greater than N68.

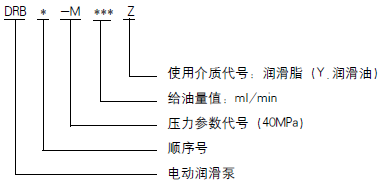

3. Model description

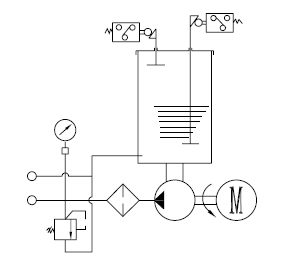

4. Graphic symbols

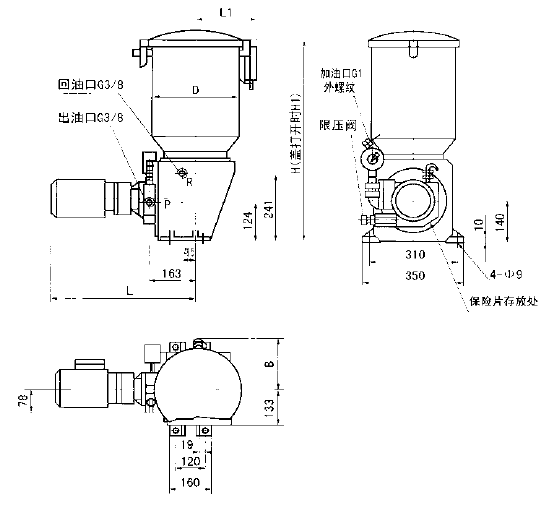

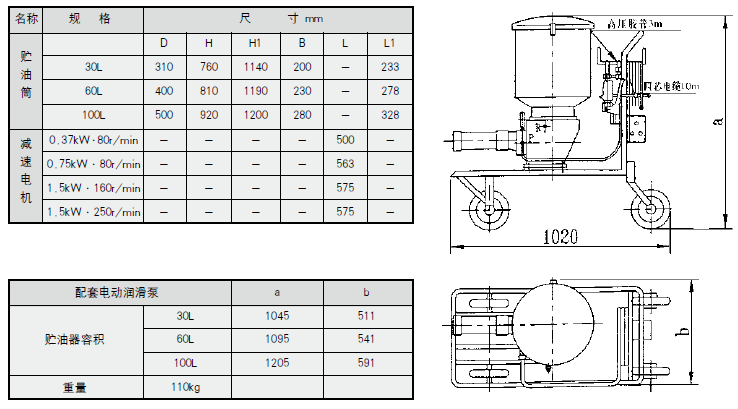

5. Dimensions

6. Action description

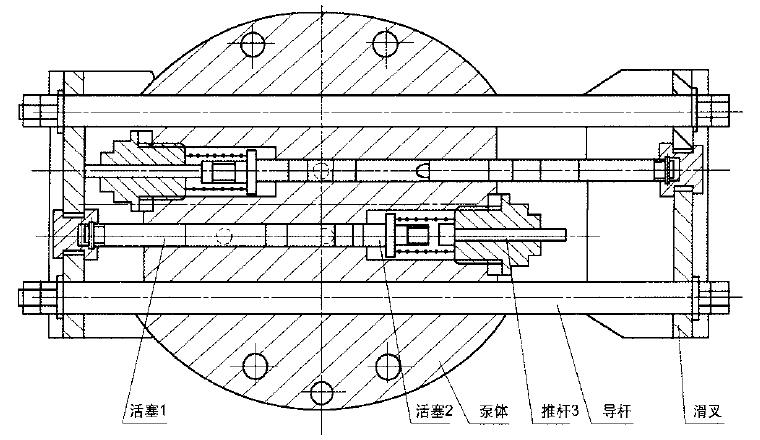

????????The reduction motor is fixed on the connecting flange with the pump device. It drives the sliding fork to perform linear reciprocating motion by driving the eccentric shaft, and drives the spiral oil pressure plate and oil scraper plate to rotate clockwise (no such mechanism is required when using lubricating oil). Grease is pressed evenly around the suction port of the pump unit.

There are two sets of pistons in the pump body. Each set of pistons is composed of 1 working piston and 2 control pistons. When the working piston in one set of pistons completes the oil suction process, the working piston in the other set of pistons presses the grease toward the oil outlet. mouth. As shown in the picture above, the upper set of pistons has completed oil absorption, and the lower set of pistons has completed oil pressing. When the sliding fork moves to the left, each starts a new working cycle. At this time, the lower group of pistons 1 and 2 moves to the left. Under the action of the spring force, piston 2 reaches the extreme position and closes the outlet, while piston 1 continues to move to the left. At this time, a vacuum is formed between pistons 2 and 1, and the degree of vacuum increases with the movement of piston 1. The left shift continues to increase, and the sliding fork moves to the extreme position. The piston 1 opens the oil suction port, and the grease is sucked in from the oil suction port. If the spring force is insufficient, the piston 2 is not pushed to the extreme position. At this time, the push rod 3 will be pushed by the sliding fork. The bottom forcefully presses piston 2 to the extreme position. At the same time, the upper group of pistons 1, 2, and 3 moves to the left. Piston 1 closes the oil suction port first, and the sucked grease moves to the left under the push of piston 1. When piston 2 When the oil outlet is opened, the movement of piston 2 and push rod 3 stops. Piston 1 continues to move to the left, pressing the grease out of the oil outlet. Pistons 1 and 2 contact the sliding fork and have moved to the limit position to complete half of the oil outlet. The cycle works like this over and over again. The two sets of pistons alternately pressure the lubricating grease out of the oil outlet. The pressed grease is filtered by the filter on the connecting flange of the pump device and then supplied to the system.

7. Instructions for use

?1. This series of electric lubrication pumps should be installed in a place where the ambient temperature is suitable, there is little dust, and it is convenient for adjustment, inspection, maintenance, disassembly and cleaning, and convenient grease refilling.

2. This series of electric lubrication pumps should be arranged in the center of the system as much as possible, shorten the length of the system piping, and maintain a low pressure drop so that the pump can generate enough pressure to overcome the back pressure of the lubrication point.

3. The set pressure of the pump pressure regulating valve can be adjusted arbitrarily within the range of 0 to 40MPa. It is not allowed to exceed the nominal pressure of the pump (40MPa) during use.

4. The filter screen of the filter at the oil outlet of the pump should be cleaned regularly to prevent clogging.

5. If the pressure reaches about 50MPa due to some system failure, the fuse will rupture. The cause must be identified and eliminated before a new fuse is installed.

6. To replenish intelligent grease into the oil reservoir, you must use an electric refueling pump to add it from the grease port of the oil reservoir.

7. The membrane-type oil level indicator in the oil reservoir is only suitable for grease. When the medium used is lubricating oil, it must be replaced with a float-type oil level indicator.

8. When the electric reducer is used for the first two months, an appropriate amount of 3# molybdenum disulfide grease must be added from the exhaust plug hole, and then every four months.

9. This series of electric lubrication pumps are for indoor installation. When used outdoors or in harsh environments, protective measures must be taken.

8. Ordering instructions

????????1. When ordering a mobile electric lubrication pump device, the required hose length and cable length must be specified in the contract. If not specified, the supply will be based on 10 meters of cable and 3 meters of hose.

2. This series of electric lubrication pumps are equipped with the following HRDK standard electric control boxes, which can be ordered according to different control requirements.

3. This series of electric lubrication pumps works at short intervals. If the user needs to work continuously for a long time, please indicate it in the contract.

9. Spare parts supplied

????????1. 10 insurance pieces (stored in the screw hole under the pump oil outlet)

2. 2 sets of filters

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more