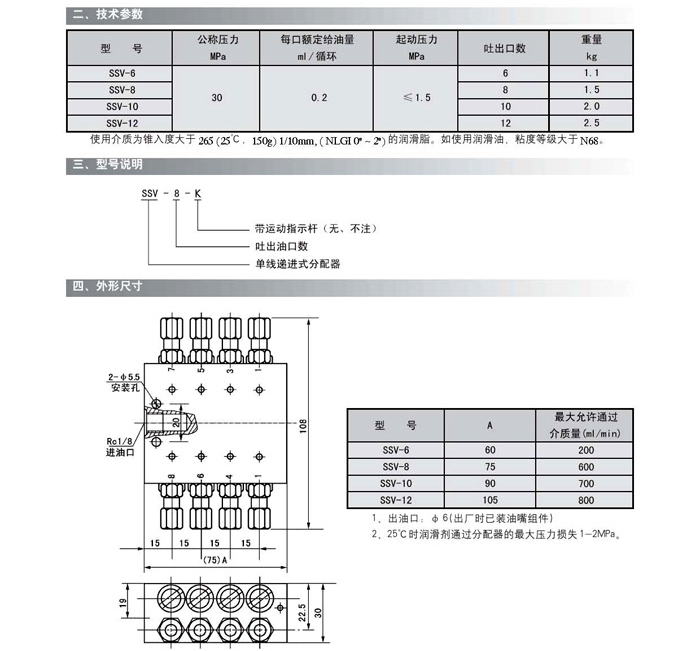

1. Conditions of use

The SSV series single-line progressive distributor is suitable for stand-alone or small dry thin oil single-line centralized lubrication systems with nominal pressures below 30 MPa. It relies on a piston inside the housing to reliably and forcefully distribute the lubricant fed in from the inlet in a predetermined amount. This type of distributor has oil outlets on the left and right sides. The installation dimensions for different outlet numbers are the same. The outlets are derivation and merged to increase the oil supply volume with manual, pneumatic or electric power.Dry thin oil lubricationThe pump can be connected to form a simple and low-cost small centralized lubrication system, or it can be connected to a single-line or double-line distributor in a large centralized lubrication system as an auxiliary distributor for secondary distribution.

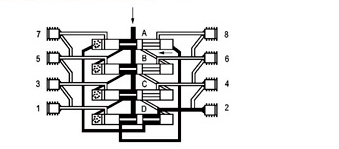

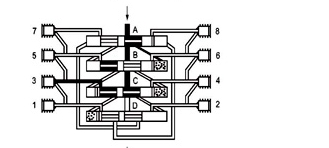

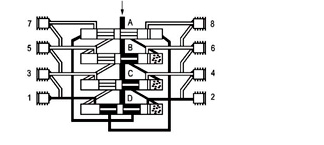

5. Action description

The lubricant enters the distributor in the direction of the arrow and is pushed to the right of piston A.

Side end. Piston A moves to the left by lubricant pressure. lie in

The lubricant at the front end of the left side of piston A is delivered to the exhaust pipe through the internal channel of the housing.

Outlet 2 and from there through the lubrication point duct to the friction point.

When piston A reaches its left end position, it leads to the right side of piston B.

The connection channel at the side end position is open. Lubricant flows to piston B right

side and move piston B to the left. Located in front of the left side of piston B

The lubricant at the end is transported to the discharge port 7 through the internal channel of the housing.

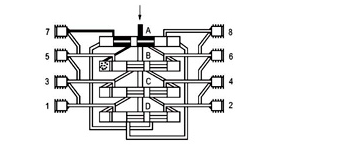

When piston B is in its left end position, it opens the

The connection channel at the terminal position on the right side of plug C is opened, so that the lubricant is pressed

The flow occurs under the action of force and causes piston C to move to the left. while located on piston C

The lubricant at the left front end is delivered to the discharge port 5.

The connection channel to piston D is now open and the lubricant pressure

Send it to the right end of piston D. Lubricant located at the front end of the left side of piston D

It will be output from outlet 3.

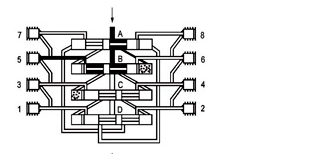

When piston D opens the connecting channel to the left terminal of piston A

Finally, the lubricant flows and pushes piston A to the right. Located in front of piston A

The lubricant on the right is delivered to discharge port 1.

At this time, pistons B to D move from left to right. Press the above in reverse order.

The direction sequence action completes a cycle and can start a new one.

New cycle.

6. Instructions for use

1. It is recommended to distribute lubricant through "two stages" at most in the system.

2. Discharge ports 1 and 2 cannot be closed at all times.

3. Always use the original discharge port and nozzle parts set.

4. When assembling, disassembling and replacing oil nozzle parts, start from the upper or lower outlet on each side.

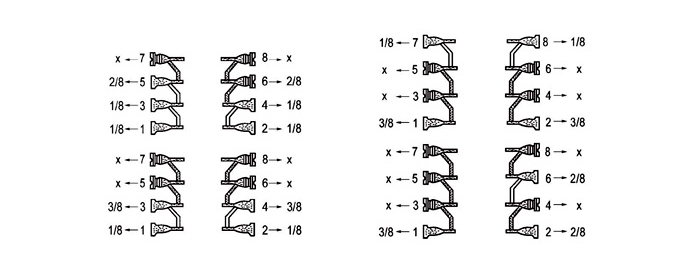

5. If the outlet needs to be closed additionally and the lubricant amount is combined (redirected to the lower outlet for discharge), the oil nozzle body must be removed and plugged with an M10×1 screw plug to connect as shown in the example below.

7. Troubleshooting and troubleshooting methods

A blockage has occurred in the equipment or in any of the connected bearings. First check whether the lubrication pump is working and whether the lubricant is supplied to the main distributor. When the distributor oil inlet joint is opened, the lubricant will overflow, proving that the distributor is the source of the fault. Connect and tighten the oil inlet joint, and open the oil inlet joint of the bearing in turn. If the lubricant overflows, then this bearing is a blocked bearing.

When the distributor is internally clogged, the distributor should be replaced. In an emergency, the dispenser can be cleaned according to the following conditions.

1. There must be a clean working space.

2. Remove the joints of each oil inlet and outlet.

3. Remove the screw plugs at both ends of the piston hole.

4. Use a soft mandrel (diameter less than 6mm, plastic rod if possible) to push out the piston.

5. Blow and clean the distributor body with compressed air.

6. Use thin iron wire (Φ1.5mm) to check the inclined hole of the flow channel in the distributor body.

7. Clean and blow the distributor body again.

8. Replace the copper gasket and reassemble the distributor.

9. Use a hand pump to check the newly assembled distributor. At this time, the starting pressure of the distributor cannot be higher than 2.5MPa. If the starting pressure is higher than 2.5MPa, the distributor should be replaced.

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more