1. Conditions of use

This product is suitable for thin oil circulation lubrication systems of large equipment such as mills, rolling mills, and motors equipped with dynamic and static pressure bearings. Its working medium is various industrial lubricants from N22 to N320 (equivalent to ISO VG22 to VG320).

According to the working principle of dynamic and static pressure lubrication, a high-pressure system is used during startup, low speed and parking, and a low-pressure system is used during normal operation to ensure that large machinery can obtain reliable lubrication at various speeds to extend the life of the main engine.

The pressure of the high-pressure part of the thin oil station is 31.5MPa, the flow rate is 2.5L/min, and the pressure of the low-pressure part is 0.4MPa; the flow rate is 16~125L/min. The thin oil station has filtration, cooling, heating and other devices as well as interlocks and alarms. , automatic control and other functions.

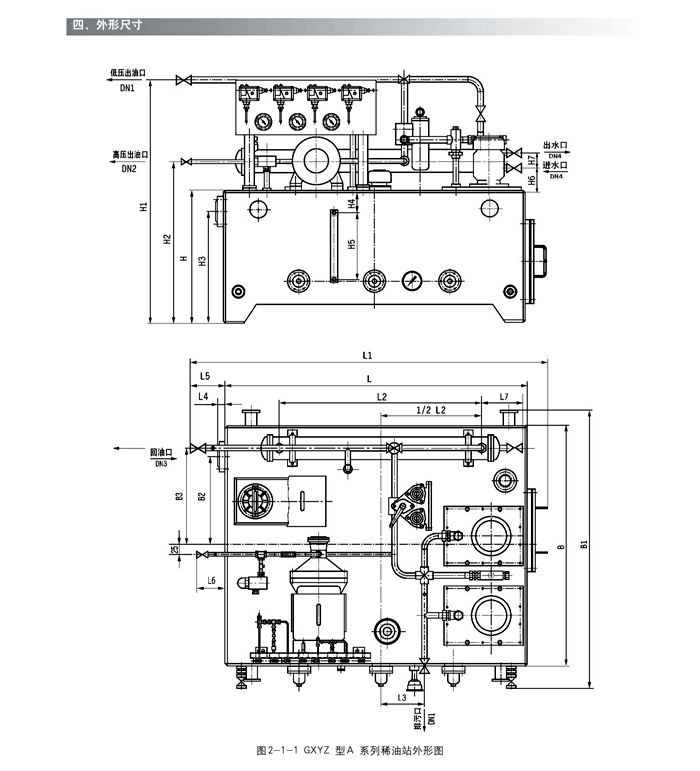

The performance parameters and dimensions of this product should comply with the regulations in the table and drawings; the device consists of a complete set of oil station, instrument panel, and electric control cabinet (can be controlled by PLC).

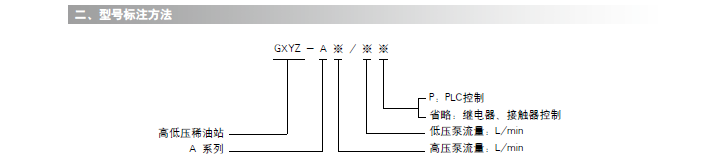

For example, if the A series is used, the high-pressure flow rate is 2.5L/min; the high-pressure pressure is 31.5MPa; the low-pressure oil supply pressure is 0.4MPa; and the high (low) pressure thin oil station with a low-pressure oil supply volume of 40L/min is controlled by PLC. Then mark it as follows: GXYZ-A2.5/40.P

3. Structural characteristics

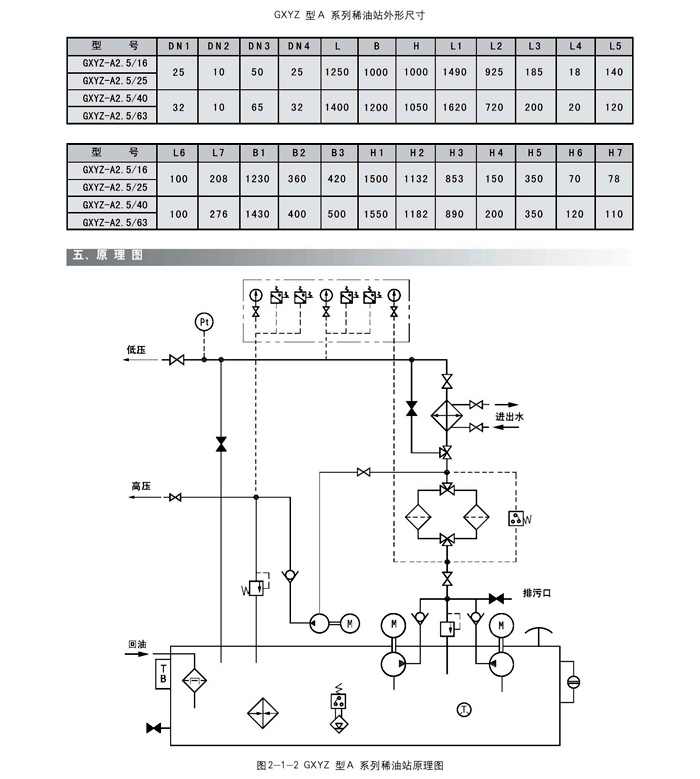

This product is mainly composed of a fuel tank (with a magnetic mesh filter inside), a low-pressure oil pump device, a high-pressure oil pump device, a double-cylinder mesh filter, a manual high-pressure oil pump, a cooler, pipes, valves, an instrument panel and an electric control cabinet. .

Before starting the main engine, start the low-pressure pump first. When the low-pressure oil supply pressure is normal, start the high-pressure oil pump with the suction port connected to the low-pressure pipeline. The high-pressure oil is sent to the static pressure bearing through the high-pressure one-way valve. When the high pressure reaches a certain value, the main shaft floats. When the speed starts, the host can start, run at low speed or stop; after the host speed is normal, the high-pressure pump can be stopped (except for low-speed operation).Process lubricationHowever, the low-pressure oil pump must supply oil normally; after the low-pressure oil pump absorbs oil from the oil tank, it passes through the one-way valve, the double-cylinder mesh filter, and the cooler to the static pressure bearing to maintain the normal oil supply of the main engine; if the main engine stops, it must be replaced regularly by The high-pressure pump and low-pressure pump supply oil, and the time relay controls the intermittent oil supply to the lubrication point.

The specific values ??of high and low pressure are controlled by the low-pressure safety valve and high-pressure relief valve in the system respectively.

When the main engine is running normally, one low-pressure pump works and the other is on standby. If the system pressure drops to a certain value, the standby pump is started and put into operation. When the normal pressure is reached, the standby pump stops. If the pressure still drops to a lower value after the backup pump is started, an alarm signal should be issued and the main engine should be considered to be shut down.

When the high-pressure plunger pump fails, the backup manual oil pump can supply oil.

The filter is placed in front of the cooler, so that the oil with smaller viscosity passes through the filter first to improve the filtration effect. One cylinder of the filter is working and the other is in standby. It is controlled by a manual switching valve.

When the oil level in the fuel tank is too low or too high, the oil level signal is sent by the oil level signal, and the oil is refueled manually or stopped.

The oil return tank is equipped with a magnetic mesh filter, which can simultaneously filter the oil and absorb iron particles in the oil.

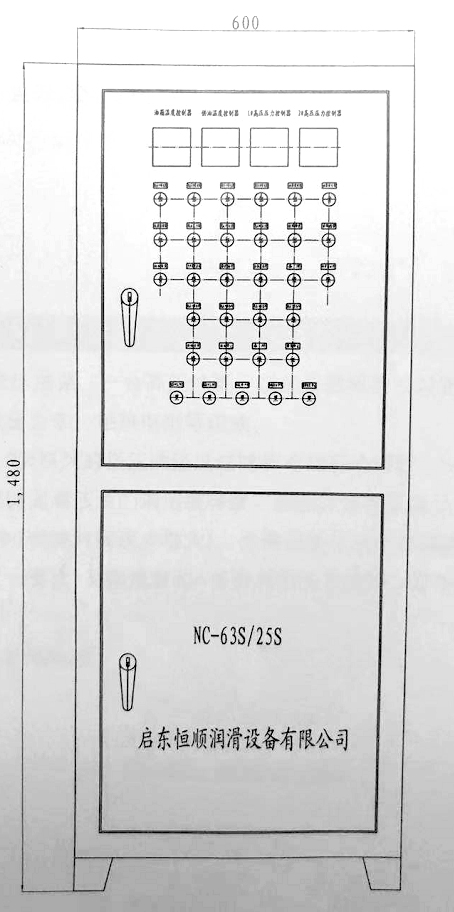

The thin oil station is supplied as a complete set with instruments and electric control boxes to display operating parameters and realize automatic control, manual control or alarm of the thin oil station.

An electric contact bimetal thermometer is installed on the fuel tank. When the oil temperature is low, it sends out a signal to manually turn on the electric heater. When the set temperature is reached, the electric heater is automatically cut off.

The oil supply port is equipped with an electric contact pressure thermometer. According to the oil supply temperature, the upper and lower limits are adjusted to control whether the cooler is used.

GXYZ type external terminal wiring diagram

6. Electric control cabinet

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more