1. Overview

The DXZ series electric dry oil station is suitable for supplying lubricant in a two-line dry oil centralized lubrication system with low lubrication frequency, piping length less than 100 meters, lubrication points less than about 300 points, and a nominal pressure of 10 MPa. The conveying device is particularly suitable for dry oil centralized lubrication systems in heavy and small mining equipment without automatic control requirements.

This series of electric dry oil stations is an electric dry oil station that is directly driven by an electric motor and drives the oil pressure plunger pump element through deceleration to discharge grease. It is generally used with a double-line oil feeder. The pressure control valve installed at the end of the system pipeline controls the direction of the solenoid valve to realize the function of supplying oil to the two main oil supply pipes of the system alternately.

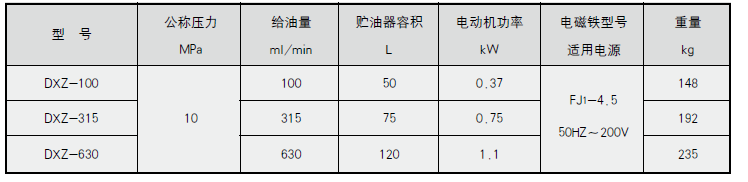

2. Technical parameters

The applicable medium is grease (NLGI 0# ~ 2#) with a penetration of not less than 265 (25℃, 150g)1/10mm.

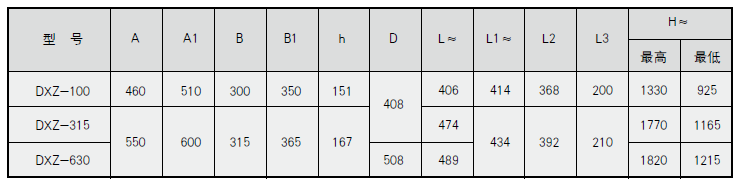

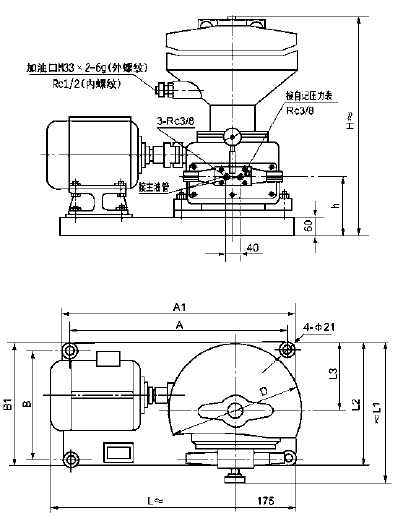

3. Dimensions

4. Model description

5. Instructions for use

1. This series of electric dry oil stations should be installed in a place where the ambient temperature is suitable, there is little dust, and it is convenient for adjustment, inspection, maintenance, disassembly and cleaning, and grease replenishment.

2. This series of electric dry oil stations are arranged in the center of the system as much as possible to shorten the length of the system piping and maintain a low pressure drop, so that the pump can generate enough pressure to overcome the back pressure of the lubrication point.

3. Before use, 50# mechanical oil must be added into the reducer to the level specified by the oil standard.

4. To replenish grease into the oil reservoir, you must use a DJB-200 electric refueling pump to add grease from the refueling port of the oil reservoir. There is no grease in the oil reservoir.Smart lubricationIt is strictly forbidden to start the electric pump without grease.

5. There is a pressure gauge interface with an Rc3/8 connection interface on the electromagnetic reversing valve. If it is not needed, it can be blocked with an R3/8 plug.

6. The pressure regulating valve on the solenoid reversing valve can be adjusted arbitrarily within the range of 0-10MPa. It is not allowed to exceed the nominal pressure of the pump (10MPa) during use.

7. After the first two months of use of the dry oil station, the electromagnets at both ends of the solenoid valve must be removed, and the joint surface should be checked to see if there is grease leaking from the ejector seal. If there is leakage, the seal should be replaced in time to avoid burning the electromagnet. , pay attention to check frequently in the future.

8. This series of electric dry oil stations is for indoor installation. When used outdoors or in harsh environments, protective measures must be taken.

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more