1. Overview

DRB-L series electric lubrication pump is suitable for dual-line dry oil centralized lubrication systems with many lubrication points, wide distribution range and high oil supply frequency. via a two-line distributor toSmart lubricationGrease is supplied to various parts to meet the needs of various machines and equipment, and is especially suitable for large units and production lines.

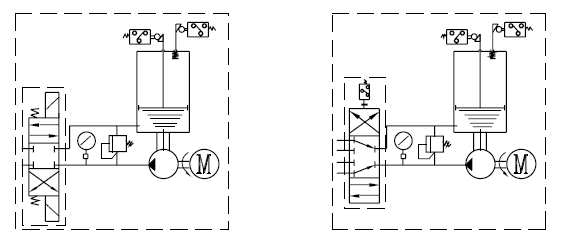

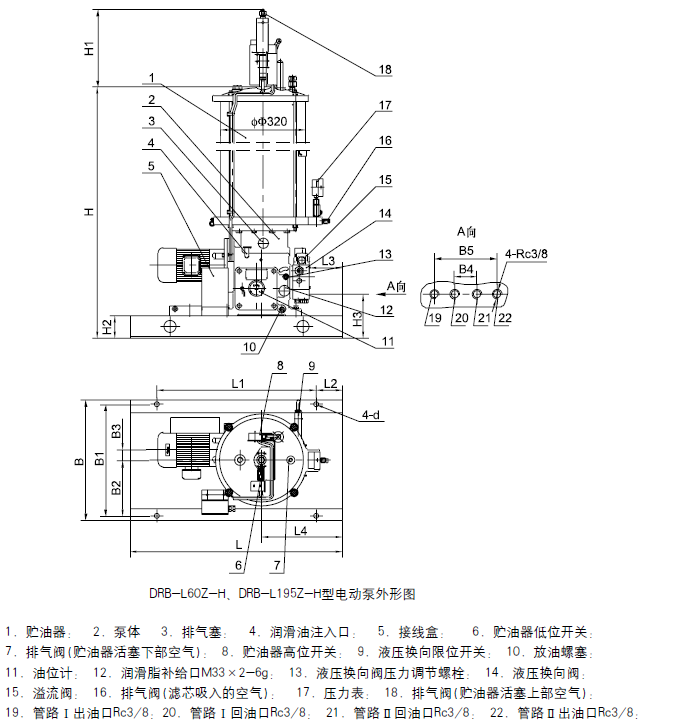

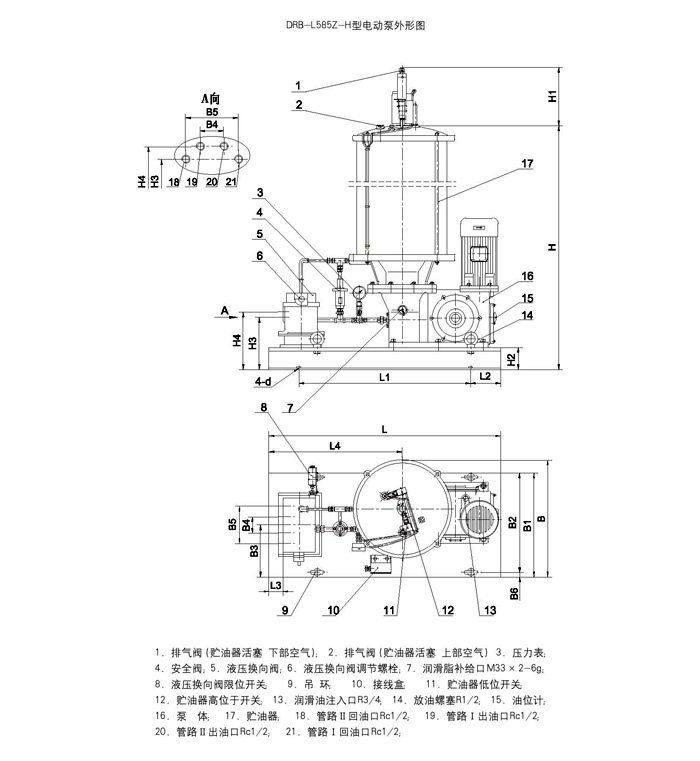

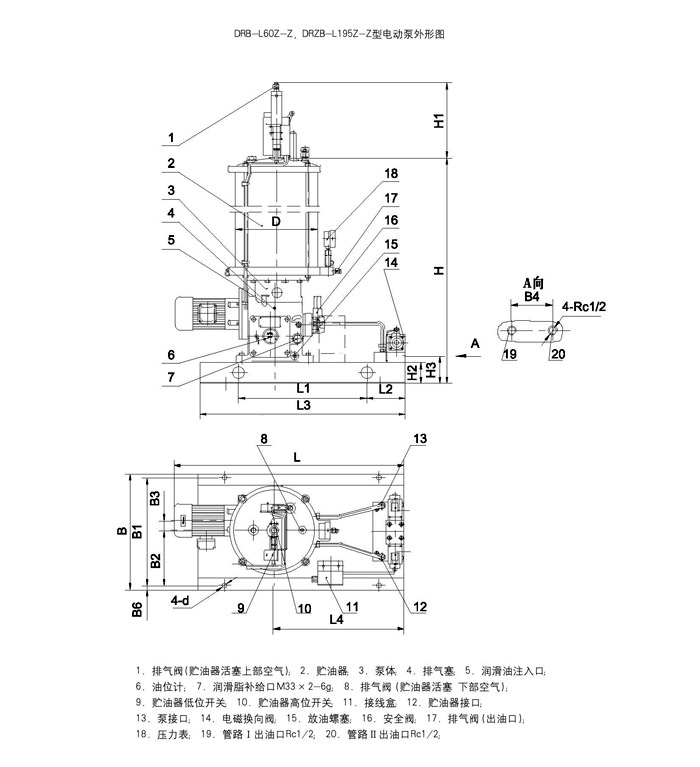

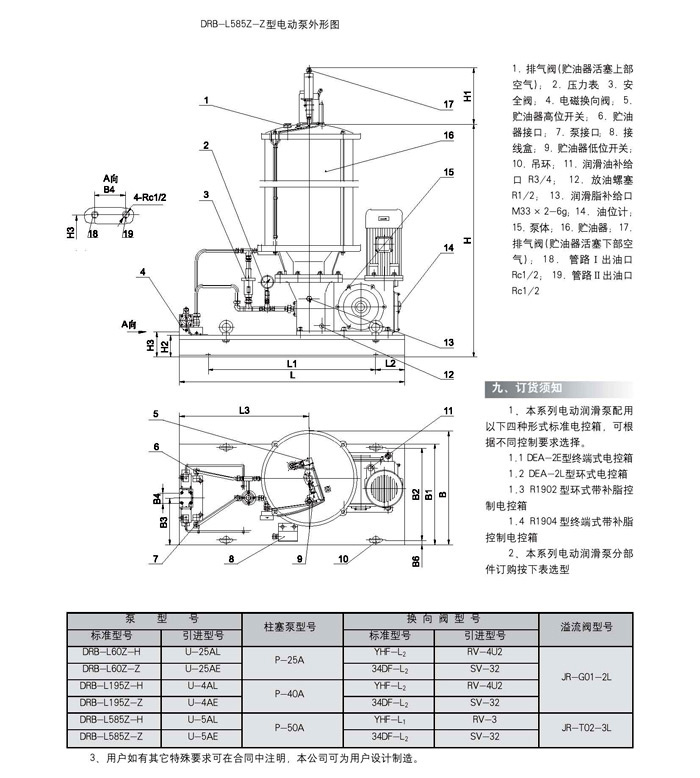

This series of electric lubrication pumps can form a two-line ring centralized lubrication system, that is, the main pipeline of the system forms a ring layout, and the system pressure at the end of the main pipeline returning to the lubrication pump controls the hydraulic reversing valve, so that the two main pipelines alternately Centralized lubrication system for supplying grease; see the specifications in the outline drawing and outline dimension table. It can also form a two-line terminal centralized lubrication system, that is, a centralized lubrication system in which the pressure control valve at the end of the main pipeline controls the electromagnetic reversing valve to alternately supply grease to the two main pipelines. See also the outline drawing and dimensions. Regulation.

This series of electric lubrication pumps adopt a double-piston mechanism, which ensures reliable operation. The deceleration mechanism is placed in the pump body. It has a compact structure and small size. It can realize automatic control with the corresponding electric control box.

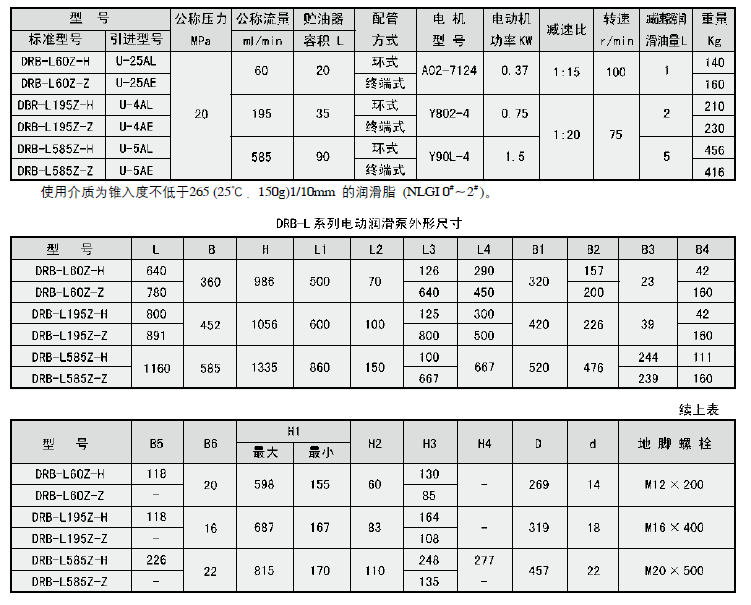

2. Technical parameters

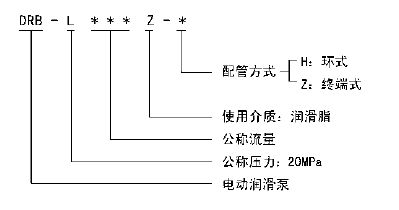

3. Model description

4. Graphic symbols

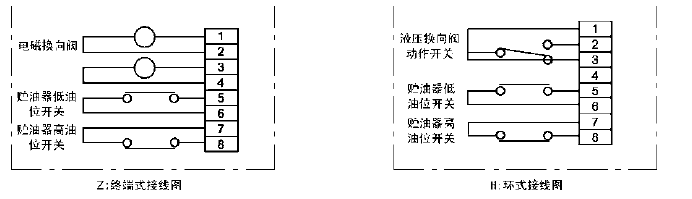

5. Wiring instructions

6. Working principle

This series of electric lubrication pumps consists of a plunger pump, an oil reservoir, a reversing valve, an electric motor and other parts. Driven by the electric motor, the plunger pump sucks grease from the oil reservoir, presses it to the reversing valve, and delivers it alternately along the two oil outlets through the reversing valve. When one oil outlet presses the grease, The other oil outlet is connected to the oil reservoir for unloading.

The annular structure electric lubrication pump is equipped with a hydraulic reversing valve, which has four interfaces. It is connected to two external oil supply main pipes and an oil return pipe led by two oil supply pipes. The oil pressure of the grease in the oil return pipe drives the reversing valve to change. Towards.

The terminal-type electric lubrication pump is equipped with an electromagnetic reversing valve. It has two interfaces and is connected to two external oil supply main pipes. It relies on the gain and loss of electricity from the electromagnet to achieve reversing oil supply.

Please refer to the instruction manual for details on the operating principle of the plunger pump reversing valve.

7. Instructions for use

1. This series of electric lubrication pumps should be installed in a place with suitable ambient temperature, less dust, low vibration, convenient for adjustment, inspection, maintenance and grease replenishment. They should be arranged in the center of the system as much as possible, shorten the length of system piping, and keep it low. The pressure drop enables the pump to generate enough pressure to overcome the resistance of the lubrication point.

2. Before use, add N220 industrial gear oil into the deceleration chamber of the plunger pump to the level specified by the oil standard.

3. To replenish grease in the oil reservoir, use an electric refueling pump to replenish grease from the supply port of the lubrication pump. The grease used should be clean and no dirt is allowed.

4. The rotation direction of the lubrication pump is one-way. When used, it must be connected according to the rotation direction specified on the rotation direction plate on the motor.

5. The standard setting pressure of the pump relief valve is 23MPa, which can be adjusted arbitrarily within the range of 0 to 20MPa. It is not allowed to exceed 15% of the nominal pressure of the pump (23MPa) during use.

6. The set pressure of the hydraulic reversing valve of the ring lubrication pump is set at 5MPa.

7. This series of electric lubrication pumps are for indoor installation. When used outdoors or in harsh environments, protective measures must be taken.

8. Appearance drawing (for appearance dimensions, please see Part 2. Technical Parameters)

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more