1. Overview

This electric refueling pump is mainly used in dry oil lubrication systems to replenish grease into the oil reservoir of dry oil lubrication devices. The pump is of a type without an oil storage drum and is placed directly on a 200L oil drum. It can be operated independently. It can be connected with the corresponding electronic control device to realize automatic grease replenishment of the electric lubrication pump system. This pump is a built-in plunger positive displacement pump with stable operation and high output pressure.

2. Technical parameters

The medium used is grease with a cone penetration of 265 ~ 385 (25℃, 150g) 1/10mm and industrial lubricating oil with a viscosity grade greater than N46.

3. Model description

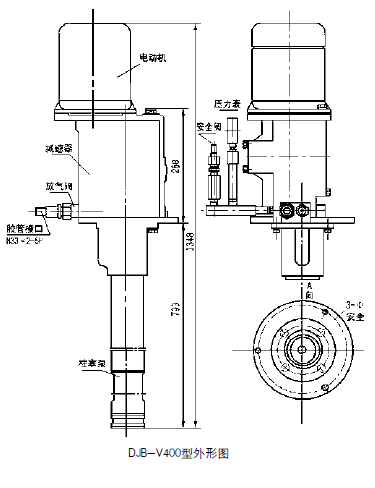

4. Overall dimensions

5. Working principle

A vertically installed motor drives the worm gear to rotate through a worm. An eccentric shaft is installed on the end face of the worm gear. The crank connecting rod drives the plunger to reciprocate up and down. The action of the inside of the piston and the one-way valve in the pipe cap completes the oil suction and pressure process through the pipeline. The oil hose is transported outward.

6. How to use

1. Rotate the wiring in the direction of the rotation arrow.

2. ConveyedSmart lubricationThe grease must be clean, uniform in texture, and within the specified viscosity range.

3. Before first use, lubricating oil (N220) should be injected into the reduction gearbox to the specified oil level.

4. After the fuel pump is started for the first time, the air release valve should be opened first and closed after normal oil discharge.

5. Do not run dry without grease in the barrel.

7. Ordering Instructions

If you need an oil storage drum or drum cover, you must indicate it in the contract when ordering.

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more