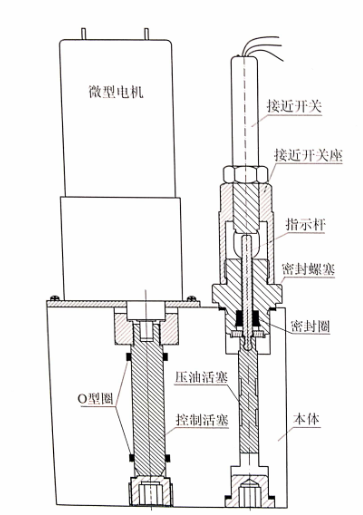

After the electronic flow controller supplies power to the micro motor, the motor starts to run, driving the control piston, and alternately refueling both ends of the oil pressure piston, so that the grease at both ends of the oil pressure piston is continuously pressed against the lubricated bearing seat. The indicator rod connected to the oil pressure piston moves up and down with the oil pressure piston, triggering the proximity switch power. (The proximity switch has two functions; one is to detect whether the oil pressure piston moves, and the other is to record the number of oil pressure piston movements.) The action signal is fed back to the electronic flow controller, and the electronic flow controller determines whether the oil supply is completed or there is a fault. If the lubrication point is blocked or the oil pressure piston is stuck, the indicator rod does not move, and the proximity switch has no signal output, it is considered a fault. After the oil supply is completed, the motor is powered off, the distributor stops working, and the next distributor starts working until all distribution is completed. After the work of the device is completed, the oil supply amount of each movement of the oil pressure piston is 0.25ml, and one cycle is 0.5ml.

Schematic diagram of the internal structure of the smart dispenser

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more