1. Overview

This machine is a small lubrication pump that can be directly installed on the wall plate or frame of the machine. The handle is manually pulled to discharge the oil.Process lubricationGrease, it can be combined with a two-line distributor to form a manual centralized lubrication system to supply quantitative grease to each lubrication point of the machine; suitable for low frequency (generally more than 8 hours of lubrication interval), and the length of the piping (D N15) does not exceed 50 m, it is used as a device for centralized lubrication and grease supply on small single-machine equipment with lubrication points not exceeding 80 points.

2. Technical parameters

The medium used is grease (NLGI 0# ~ 1#) with a cone penetration of not less than 310 ~ 385 (25℃, 150g) 1/10mm. The applicable ambient temperature is +10℃ ~ +40℃.

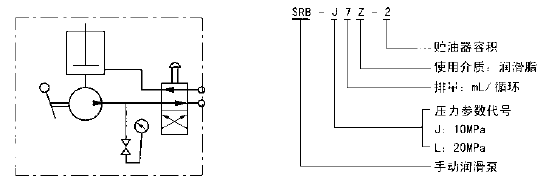

3. Schematic diagram

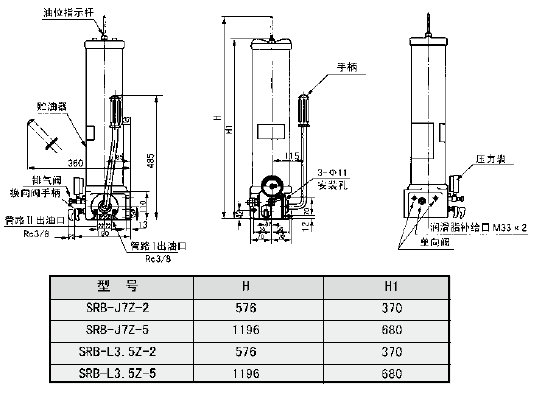

4. Overall dimensions

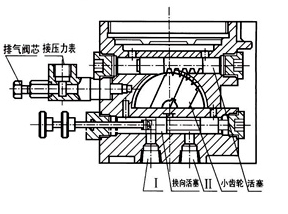

6. Action description

The grease supply of the manual lubrication pump is realized by manually swinging the handle and driving the rack-mounted oil supply plunger to reciprocate through a pinion. When the plunger is at the right end limit position, the oil pressure in the right end chamber ends, and the oil suction in the left end chamber is completed. When swinging the handle and the plunger moves to the left, first close the suction port of the left chamber, squeeze the grease to push open the one-way valve, enter the oil supply main line II through the reversing valve flow channel, and discharge into the main oil supply line II; at this time, the right chamber of the plunger The volume increases to form a vacuum, and the degree of vacuum gradually increases. When the plunger moves to the extreme position of the left end, the suction port of the right chamber opens. Under the action of the atmosphere, the grease is sucked in. In reverse of the above action, the grease pushes open in one direction. The valve enters the main oil supply line JJ through the reversing valve flow channel and is discharged. The reversal during the oil supply process is realized by the reversal of the reversing valve. When the reversing valve handle is pushed forward, the grease is discharged from the main line II. When the reversing valve handle is pulled out, the grease is discharged from the main line I.

7. Operation method

1. Push the reversing valve hand button to the extreme position and supply oil from the oil supply main pipe II.

2. The swing handle moves forward and backward, and the pointer of the pressure gauge fluctuates, which proves that the series distributor is supplying oil.

3. The pressure gauge on the pump indicates that the pressure value rises and remains stable, proving that all actions of the system distributor are completed.

4. Pull out the reversing valve hand button to the extreme position, supply oil from the oil supply main pipe I, and operate according to items 2 and 3.

5. Remove the pipeline pressure, switch to the oil supply main pipe II, prepare for the next working cycle, and move the handle to the vertical position.

8. Instructions for use

1. The manual lubrication pump should be installed vertically. There should be space above and around the pump for the indicator rod to rise and for grease replenishment. When it needs to be installed outdoors or in harsh environments, the pump should be placed in a protective cover.

2. When there is no grease in the oil reservoir, the handle is not allowed to be operated, and the oil level should be replenished in time.

3. To add grease to the oil reservoir, a special manual or electric refueling pump must be used to fill from the refueling port.

4. The operating pressure of the pump must not exceed the nominal pressure of the pump.

5. The filter at the pump refueling port should be inspected and cleaned regularly.

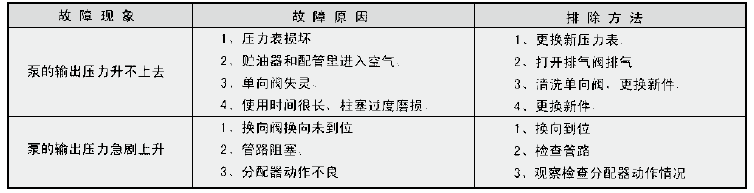

9. Common troubleshooting

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more