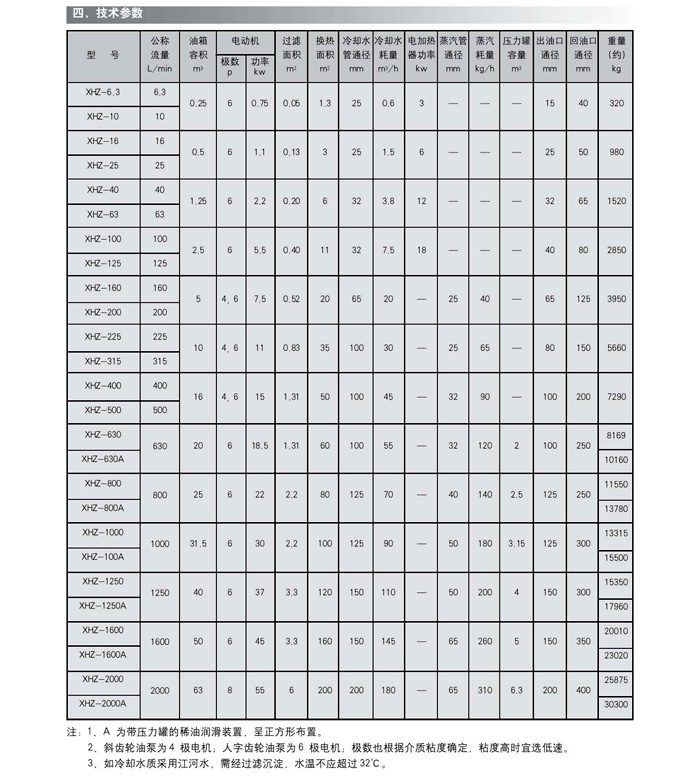

1. Conditions of use

This product is suitable for single-distribution thin oil circulating lubrication systems of metallurgy, heavy-duty, mining and other mechanical equipment. The working medium viscosity grade is industrial lubricating oil of N22-N460 (equivalent to ISOV G22-460). The cooling device adopts tubular oil. cooler.

The nominal oil supply pressure of the thin oil lubrication device is 0.63MP a; the filtration accuracy is 0.08mm when the viscosity is low; it is 0.12mm when the viscosity is high; the cooling water temperature is ≤30℃; the cooling water pressure is <0.4MPa; the oil inlet of the cooler When the temperature is 50°C, the temperature drop of the lubricating oil is ≥8°C, and the steam pressure is 0.2-0.4MPa; the pump port pressure should be greater than 0.63MPa.

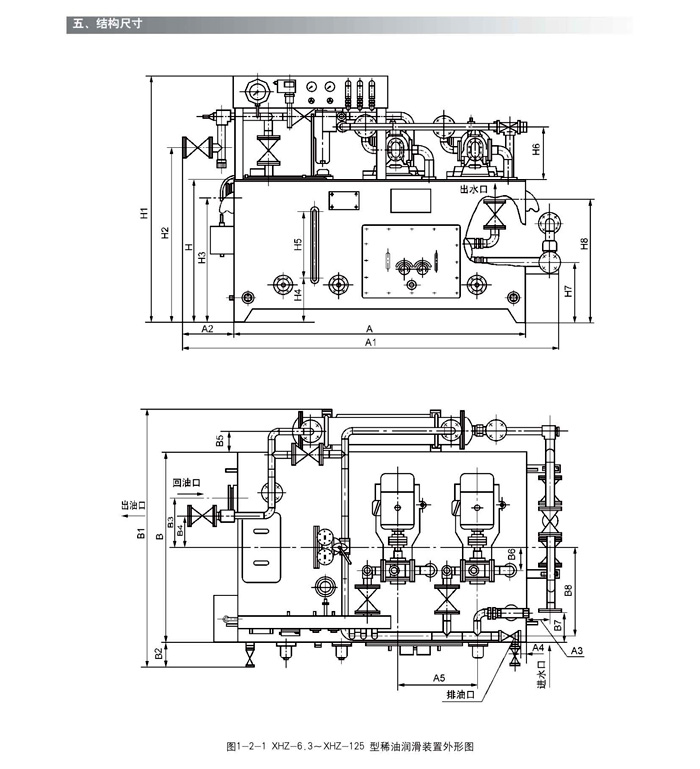

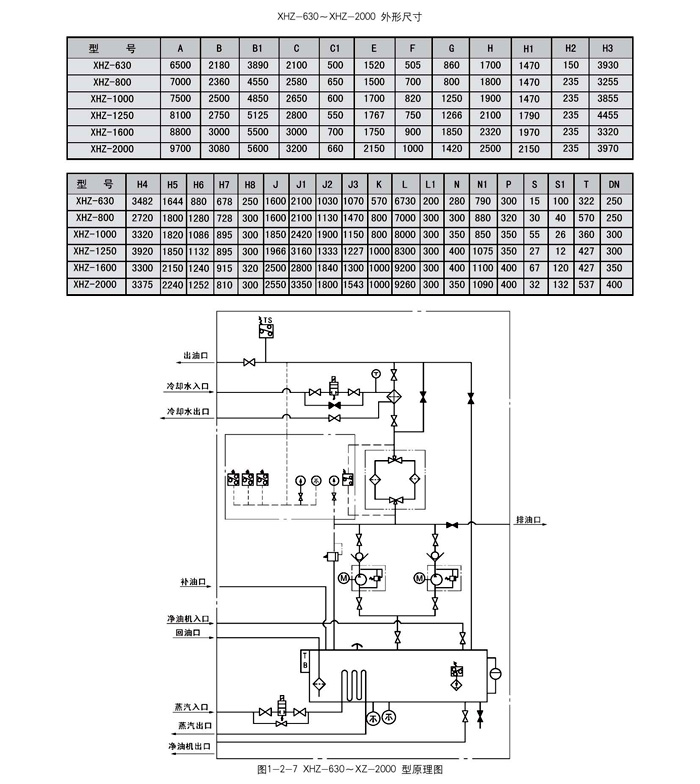

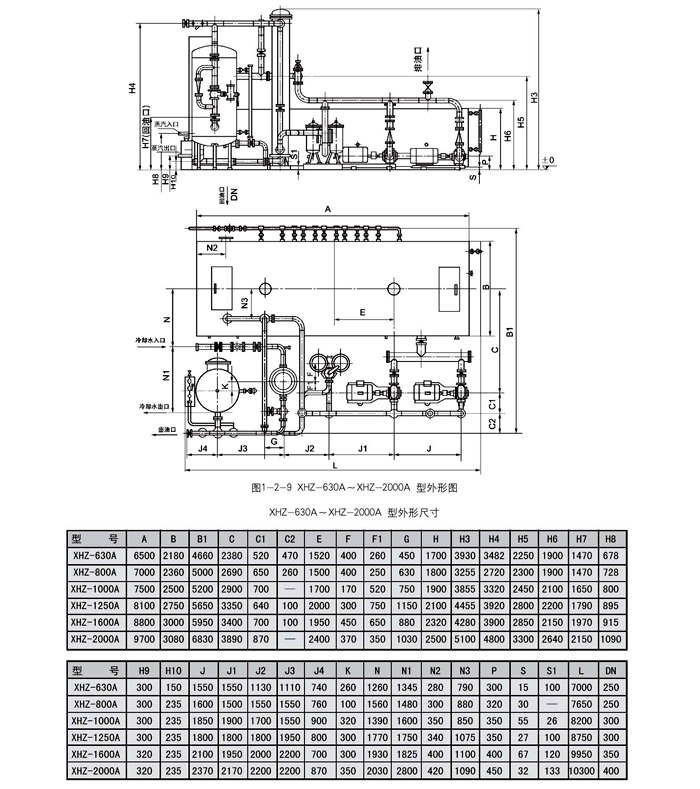

The small thin oil lubrication devices of XH Z-6.3 ~ XH Z-125 are shipped from the factory as a whole; the medium-sized thin oil lubrication devices of XH Z-160 ~ Large-scale thin oil lubrication devices from 630A to 2000A (with pressure tank plus “A”) are supplied in complete sets and are welded and assembled on site.

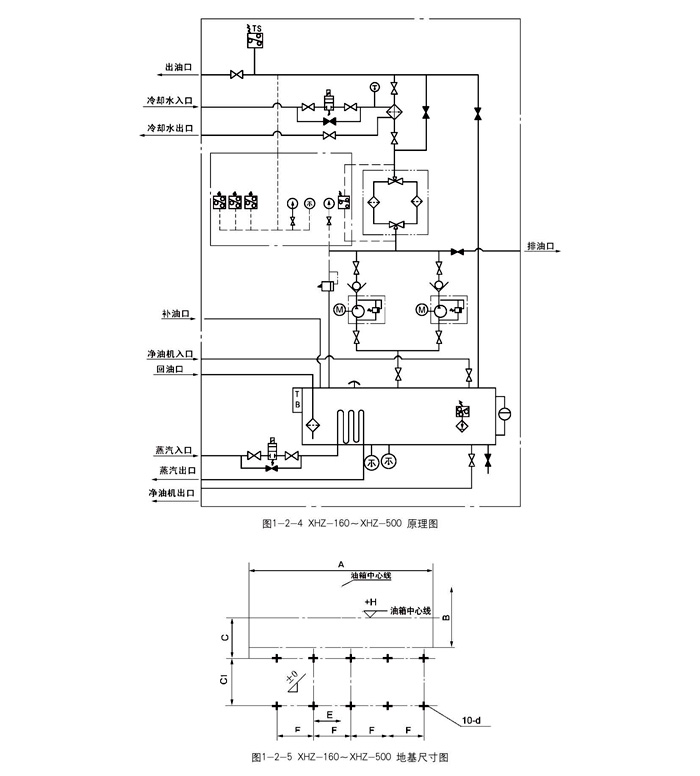

2. Working principle

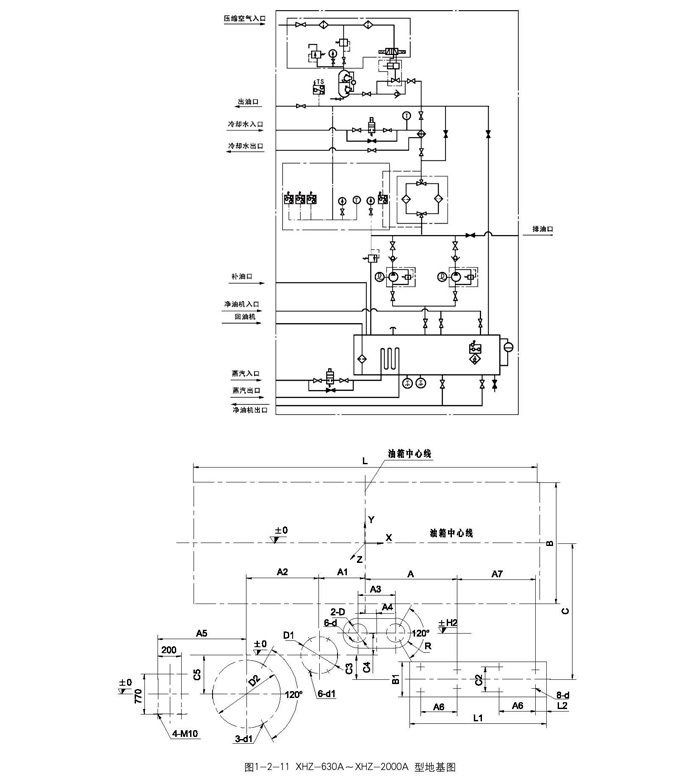

The working principle of this thin oil lubrication device is as follows:

The oil is discharged from the oil pump, passes through the one-way valve, stop valve, double-cylinder mesh filter and oil cooler and is directly sent toProcess lubricationpoint, and then flows back to the tank along the system's oil return main pipe through the oil return filter. The nominal pressure of the pump is 0.63MPa (i.e., the maximum outlet pressure of the pump), and the oil supply pressure of the thin oil lubrication device is 0.5MPa (i.e., the oil outlet pressure). The thin oil lubrication device equipped with a pressure tank has an air source pressure of 0.5~0.6MPa.

During normal operation, one gear pump is working and one is on standby. They are controlled by a transfer switch to be used alternately, and they are started and stopped by a button switch. The output end of the pump is equipped with a safety valve to prevent the oil pump from over-cutting. The opening pressure of this valve is set to 0.63MPa. The pressure of the system is controlled by the pressure switch. When the system pressure reaches the normal setting value, the main engine can be started. When the system pressure is lower than a certain setting value, the backup pump automatically starts until the pressure returns to normal. If the system pressure continues to decrease and is lower than the low-pressure set value, a low-pressure accident alarm signal will be issued and the host will be ordered to stop and troubleshoot.

3. Structural characteristics

1. A differential pressure signal is installed on the double-cylinder filter. When the pressure difference between the inlet and outlet of the filter exceeds 0.10~0.15MPa, the differential pressure signal will send out an alarm signal to notify the switching of the working filter cartridge for cleaning or replacement of the filter. Net (this device is designed before the cooler device; those with higher oil viscosity are more suitable).

2. A direct-reading thermometer and an electromagnetic water valve are installed at the water inlet of the cooler to observe the inlet water temperature and control the on or off of the cooling water. At the oil outlet of the system, an electrical contact, thermometer and temperature controller are installed to control the working oil temperature; when the outlet oil temperature is higher than a certain set temperature, the solenoid water valve automatically opens and the cooler is put in Work until the oil temperature returns to normal. If the cooler has been put into operation and the oil temperature of the system continues to rise and reaches a high temperature, the temperature controller will issue an oil temperature overheating alarm signal. When the cooler needs to be replaced or repaired, the inlet and outlet valves of the cooler can be closed, the bypass valve can be opened, and the oil will be sent directly to the lubrication point without passing through the cooler.

3. There are two electric contact thermometers and two liquid level switches installed on the oil tank. When the oil temperature in the oil tank is lower than a certain set temperature, the electric heater is powered on or the steam valve is opened to heat the oil until it reaches normal operation. to the oil temperature. When the temperature of the oil in the tank is lower than the low setting temperature, the oil pump cannot start and the oil in the tank needs to be heated. When the liquid level in the fuel tank reaches the upper or lower limit, the liquid level switch sends an alarm signal.

4. Those with "A" after the model are devices with a pressure tank, which can meet the requirements of an accident or sudden power outage. The oil stored in the pressure tank can be used as a temporary pressure oil source to supply oil to the system for a short period of time, but please note that General one-way valves on pressure tanks should be installed horizontally and not downwards (smaller swing-type one-way valves are allowed to be installed upwards), and the accompanying drawings should be changed accordingly.

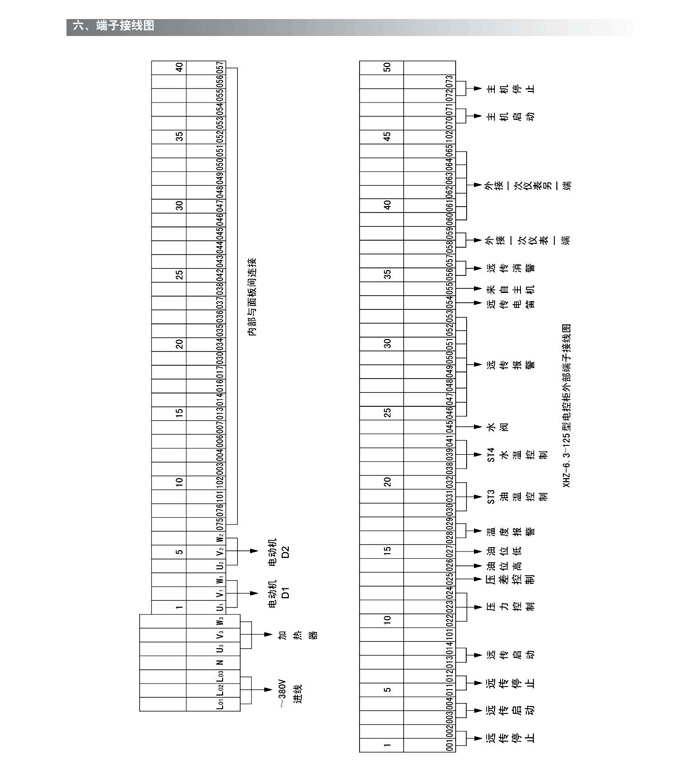

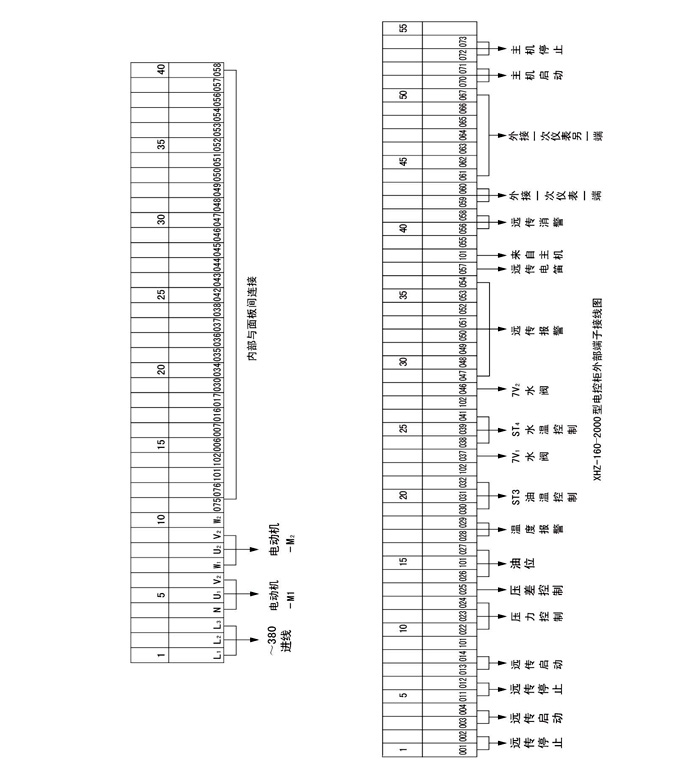

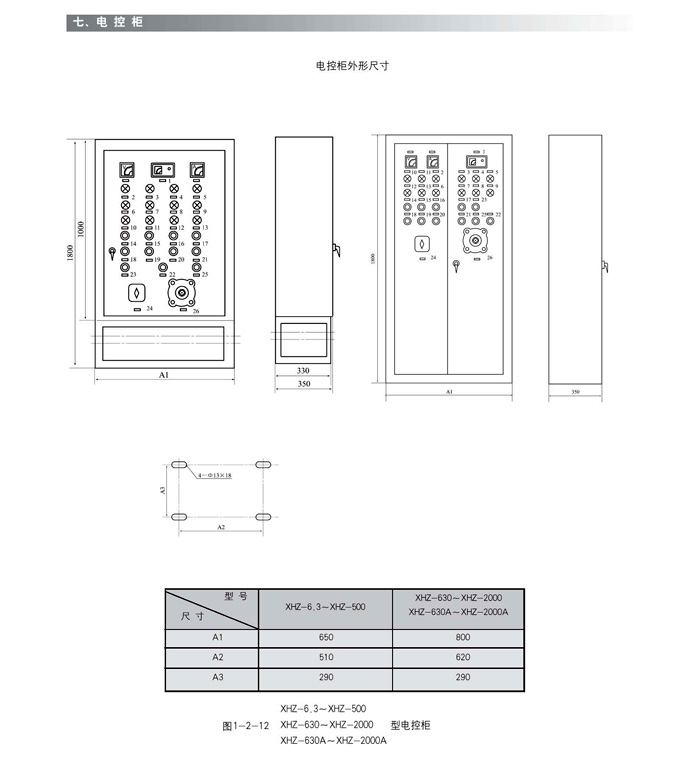

5. Equipped with an electric control cabinet and instrument panel, it is convenient to observe operating parameters and can realize automatic control and accident alarm.

Address: No. 010, Xinglong Road, Huilong Industrial Park, Qidong City

Sales hotline: 0513-83637668

Company fax: 0513-83637098

After-sales service: 0513-83635700

Website: delcan.cn

E-mail:qd3637668@163.com

Scan to learn more